MTLB - laser strip thickness gauge for sintering lines

Thickness Gauge for thickness measuring of metal strips coated on one side by a metallic powder (Sn,Ni,Cu; Pb,Sn,Cu…) for slide bearings production. Types: MTLB-150, MTLB-250

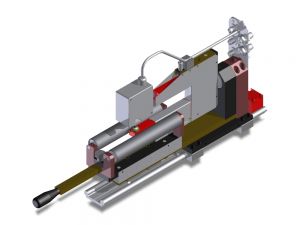

The gauge combines the contact measurement (diamond contact at the bottom side of the strip) with the contactless measurement by the laser sensor positioned above the top powder coated side. The floating measuring head ensures a proper measurement at a right angle to the strip. A couple of guiding rollers ensures a free passing of the strip through the gauge and copying of the wavy strip. This provides much more accurate measurement of powder coated strip thickness than using of two laser heads. The measuring head is moved into working position manually.

The diamond contact is permanently touching the measured strip and has a long service life. In actual fact is the thickness measurement provided by the laser sensor.

The control unit enables:

- monitoring of the total thickness on digital display

- setting and monitoring of lower and upper limits

- simple digital calibration of the gauge

Features:

- absolute digital display of the measured thickness

- independence of the measured material type

- no mechanical adjustment of the gauging head for nominal thickness

- easy operation

- 5 years warranty on diamond contact

Optional accessories:

- analogue output for AGC 0 - 20 mA

- serial data output module (PROFINET, PROFIBUS,...)

- industrial PC with PP-VIZUAL statistics processing system

| Parameter | MTLB-150 (-250) | |

|---|---|---|

| Resolution | 0,001 mm .0001" |

|

| Strip thickness range | 0,03 - 6 mm .01 - 0.24" |

|

| Max. thickness measurement error | ≤ 5 µm ≤ .0002" |

|

| Max. measurement depth from the strip edge | 150 mm (250 mm) 5.9" (9,8") |

|

| Max. strip speed | 30 m/min 100 ft/min |

|