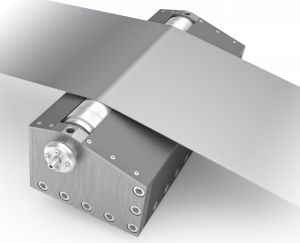

STM - Shapemeter roll for strip flatness measurement

Metal strip flatness measurement system - Sectional strip tension meter - Shapemeter roll (Shape-roll, Measuring-roll). Type: STM

Shapemeter roll - sectional strip tension meter - is designed for evaluating of metal strip flatness in cold rolling mills. The principle of the flatness evaluation is based on measuring of pressure forces of a metal strip in the multiple zones of the measuring roll deflector. A visual unit displays measured flatness and tensions across the strip in real time on monitor in the form of a column and flat graphical mapping.

Advantages

- flatness display in I-units

- strip tension distribution display in Newtons

- measuring the flatness and the spread of the tensile force from zero speed of the strip

- measuring the total tensile force of the strip

- no mark on the strip thanks to small bending angle 5°-10°

- affordably priced measuring equipment

- simple construction for maintenance and calibration

Features

- custom built measuring roll with sensitive measuring zones

- industrial PC with visualisation and archiving software

- data output: PROFIBUS or per customer requirement

- OEM version without Industrial PC is possible

| Parameter | Value |

|---|---|

| Measurement error | <0.15% of full range |

| Strip temperature max. | 220°C (438°F) |

| Width of each zone | 33.5 mm (1.32") |

| Max. vertical force each zone | 14 000 N |

| Environmental protection of sensors | IP68 |

Attached videos

STM-1200 on electrical seel strip in VIZ-STEEL Russia (NLMK group):

STM-1730-52-150 on on a tension levelling line:

STM-400 on lead strip in Johnson Controls, Inc. Mexico:

Reference letter

Attached files

- I-Units chart - how to measure with a manual gauge – (312.55 kB)

- Catalogue_English – (3.44 MB)